Select a different country or region to see content for your location.

United States

23:31:01 GMT+0000 (Coordinated Universal Time)

K3984-3920

Tapered roller bearing

Tapered roller bearings K-Series, in inch sizes, separable, adjusted or in pairs

Replaces

K3984.3920, K3984.3920.F22

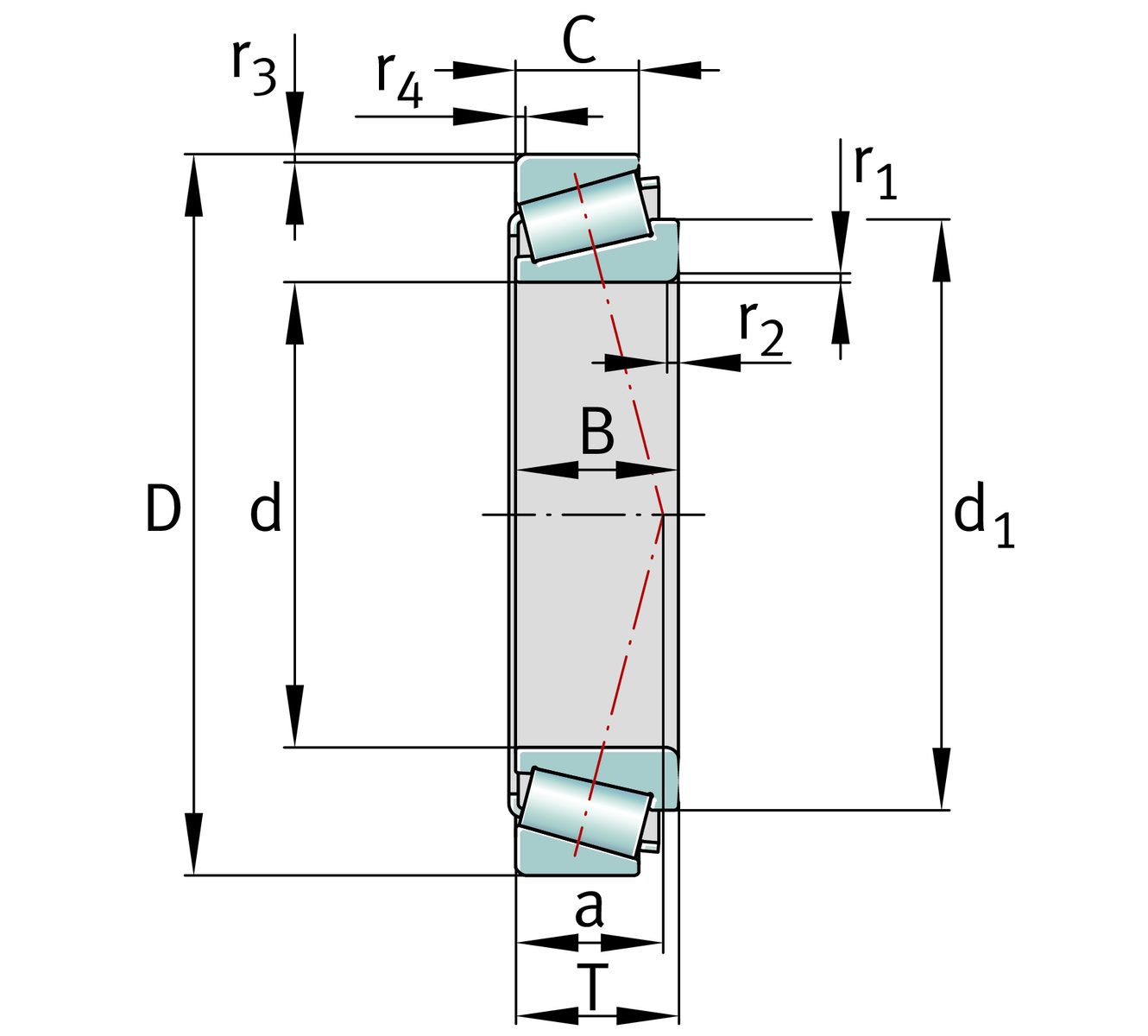

Main Dimensions & Performance Data

| d | 66,675 mm | Bore diameter |

| D | 112,712 mm | Outside diameter |

| B | 30,048 mm | Breite des Innenringes |

| C | 23,812 mm | Breite des Außenringes |

| T | 30,162 mm | Width, total |

| Cr | 119.000 N | Basic dynamic load rating, radial |

| C0r | 176.000 N | Basic static load rating, radial |

| Cur | 22.400 N | Ermüdungsgrenzbelastung, radial |

| nG | 6.300 1/min | Grenzdrehzahl |

| nϑr | 4.300 1/min | Thermische Bezugsdrehzahl |

| ≈m | 1,2 kg | Weight |

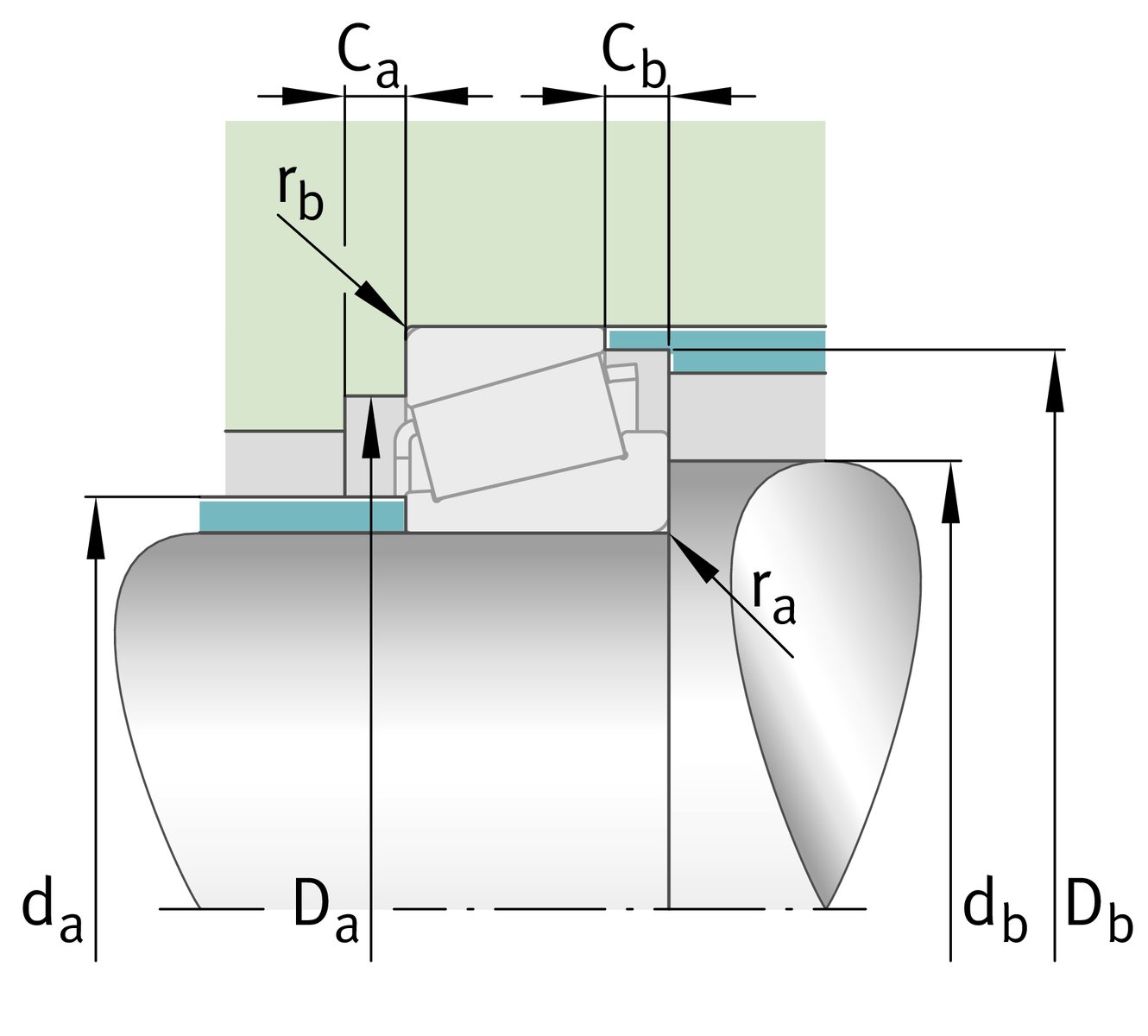

Mounting dimensions

| da max | 74 mm | Maximaler Durchmesser der Wellenschulter |

| db min | 80 mm | Minimaler Durchmesser der Wellenschulter |

| Da min | 99 mm | Minimaler Durchmesser der Gehäuseschulter |

| Db min | 106 mm | Minimaler Durchmesser der Gehäuseschulter |

| Ca min | 4 mm | Minimaler axialer Freiraum |

| Cb min | 6 mm | Minimaler axialer Freiraum |

| ra max | 3,6 mm | Maximaler Hohlkehlradius an der Welle |

| rb max | 3,3 mm | Maximaler Hohlkehlradius am Gehäuse |

Dimensions

| r1, 2 min | 3,6 mm | Minimaler Kantenabstand an der breiten Stirnseite des Innenringes |

| r3, 4 min | 3,3 mm | Minimaler Kantenabstand an der breiten Stirnseite des Außenringes |

| a | 26 mm | Abstand Druckkegelspitze |

| d1 | 89 mm | Führungsborddurchmesser des Innenringes |

Temperature range

| Tmin | -30 °C | Betriebstemperatur min. |

| Tmax | 120 °C | Betriebstemperatur max. |

Calculation factors

| e | 0,4 | Grenzwert für Fa/Fr für die Anwendbarkeit der versch. Werte der Faktoren X und Y |

| Y | 1,49 | Dynamischer Axiallastfaktor |

| Y0 | 0,82 | Statischer Axiallastfaktor |

Your current product variant

| Tolerance class | ABMA4 | Class 4 (ANSI/ABMA 19.2:2013) |

| Heat treatment | Standard | |

| Cage | Standard | Sheet steel cage, window cage, roller-guided |

| Quality level | Standard | |

| Number of rolling element rows | 1 | Single-row design |

Characteristics

Operating conditions for bearing K3984-3920

In work for K3984-3920

CO₂e caused by friction during operation

Comprehensive information with immediate calculations of the CO2e emissions of our rotative products in various application scenarios.

Load

*MandatoryMotion Influences

*Mandatory Preset calculation parameters

Arcanol MULTI2

Greasenormal cleanliness

Contamination70°C

Operating Temperature20°C

Ambient Temperature Choose your calculations

Powered by Bearinx

Please add the remaining conditions.

CO₂e emissions

For Production info_outline

-

Rating life

Total Rating Life (Lh10)

-

Static safety (S0)

-

Your feedback helps us to continuously improve our product.

All

English

2017-08-15 | Katalog | MH1 Dismounting Hydraulic | Englisch

Dismounting of rolling bearings - Hydraulic dismounting

2017-08-15 | Katalog | MH1 Dismounting Mechanical | Englisch

Dismounting of rolling bearings - Mechanical dismounting

2017-09-15 | Katalog | MH1 Thermal mounting | Englisch

Mounting of rolling bearing - Thermal mounting

2017-08-15 | Katalog | MH1 Mounting Mechanical | Englisch

Mounting of rolling bearings - Mechanical mounting

2017-09-15 | Katalog | MH1 Mounting angular contact | Englisch

Mounting of rolling bearings -Mounting of angular contact ball bearings and tapered roller bearings

2017-09-15 | Katalog | MH1 Services | Englisch

Services

2017-09-15 | Katalog | MH1 Tables | Englisch

Tables

2017-09-15 | Katalog | MH1 Technical principles | Englisch