Shaft and support rail units

Features

Shaft and support rail units TS..W are composite units comprising a raceway shaft screw mounted to an aluminium support rail. The shaft protrudes approx. 2 mm to 3 mm beyond the end of the support rail at both ends.

The raceway shaft is made from quenched and tempered steel. Corrosion-resistant design available by agreement.

Shaft and support rail units are composed of several individual sections depending on their length.

Shafts made from special materials such as those with coatings are available by agreement.

Multi-piece raceway shafts and shaft and support rail units

If the guidance systems are of such a length that shaft and support rail units TS..W cannot be achieved using single-piece shafts, shafts and support rails are supplied as multi-piece units, ➤ Figure. The joint locations on the shaft sections have mortice and tenon joints and are polished.

The joint locations on the shafts and support rails are offset from each other.

The maximum length of single-piece shaft and support rail units is 6 000 mm.

Shaft and support rail unit

with multiple support rail sections

Design and safety guidelines

Hole patterns for shaft and support rail units

Unless stated otherwise, raceway shafts and shaft and support rail units are supplied with a symmetrical hole pattern, ➤ Figure to ➤ Figure.

An asymmetrical hole pattern may be available at customer request. In this case, aL max ≧ aL ≧ aL min and aR max ≧ aR ≧ aR min.

Hole patterns for shafts

with one row of holes

Hole patterns for support rails

with two rows of holes

Hole patterns

for shaft and support rail unit TSUW

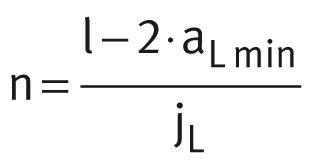

Maximum number of pitches between holes

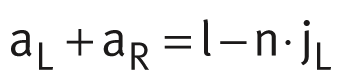

The number of pitches between holes is the rounded whole number equivalent to: The distances aL and aR are generally determined by:

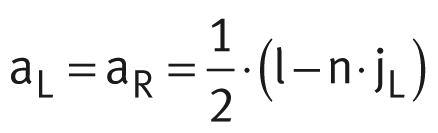

The distances aL and aR are generally determined by: For raceway shafts and shaft and support rail units with a symmetrical hole pattern:

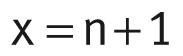

For raceway shafts and shaft and support rail units with a symmetrical hole pattern: Number of holes:

Number of holes:

| n | mm | Maximum possible number of pitches or recommended distance between screws on shaft and support rail units with T-slots |

| l | mm | Length of shaft and support rail unit |

| aL, aR | mm | Distance between start or end of shaft and support rail unit and nearest hole |

| aL min, aR min | mm | Minimum values for aL, aR according to dimension tables |

| aL max, aR max | mm | Maximum values for aL, aR according to dimension tables |

| jL | mm | Distance between holes |

| x | mm | Number of holes on shaft and support rail units with T-slots: number of screws. |

ACHTUNG

If the minimum and maximum values for aL and aR are not observed, the counterbores of the holes may be intersected. The position aL for shaft and support rail unit TSUW is shown in ➤ Figure .

Accuracy

Length tolerances

for shafts and shaft and support rail units

The length tolerances are shown in the table.

Tolerances

Length of shaft or shaft and support rail unit L | Length tolerance | |||

|---|---|---|---|---|

mm | mm | |||

Single-piece and multi-piece raceway shaft and support rail units | ±0,1% of total length | |||

| L ≦ | 400 | ±0,5 | |

400 | < | L ≦ | 1 000 | ±0,8 |

1 000 | < | L ≦ | 2 000 | ±1,2 |

2 000 | < | L ≦ | 4 000 | ±2 |

4 000 | < | L ≦ | 6 000 | ±3 |